Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model: XGJ560

merk: YULONG

verpakkingen: Geschikt voor zeevracht of luchtvracht

produktiviteit: 1.5-2t/h

vervoer: Ocean,Air

Plaats van herkomst: Shandong, China

Ondersteuning over: 500 sets per year

Certificaat: CE,ISO, SGS

GS-code: 84793000

Haven: Qingdao

betaling Type: L/C,T/T

Incoterm: FOB,CFR,CIF,EXW

XGJ-serie efficiënte biomassa landbouw gewasafval pellet mill is ons belangrijkste product dat de essentie van pellet mill in overzeese markt heeft aangenomen. De hartdelen "dubbellaagse matrijs" heeft een unieke structurele assemblage en "rollers" zijn gemaakt van zeer draagbare legeringsmaterialen. twee delen hebben de volgende karakters: bijzonder ontwerp, redelijke structuur, lage energie, hoge efficiëntie, lange lift enzovoort. Door veel hard werk van technische experts heeft ons bedrijf dit typische patentproduct ontwikkeld dat eerst op de binnenlandse markt naar voren komt. machine heeft het land leeg in verticale invoer voor de matrijskorrelmolen en heeft het internationale geavanceerde niveau bereikt.

Yulong Brand Biomassa Landbouw Gewas Afval pelletmolen voordelen

|

1 |

Double-layer stainless steel ring die, up and down side. One ring die can be using 2 times by turn it over. Reduce operating costs. |

|

2 |

Vertical ring die, feeding vertically, the raw materials can follow to the pellet machine pelleting room directly. |

|

3 |

Vertical ring die structure, easy for heating dissipation, which can keep the machine running continually. |

|

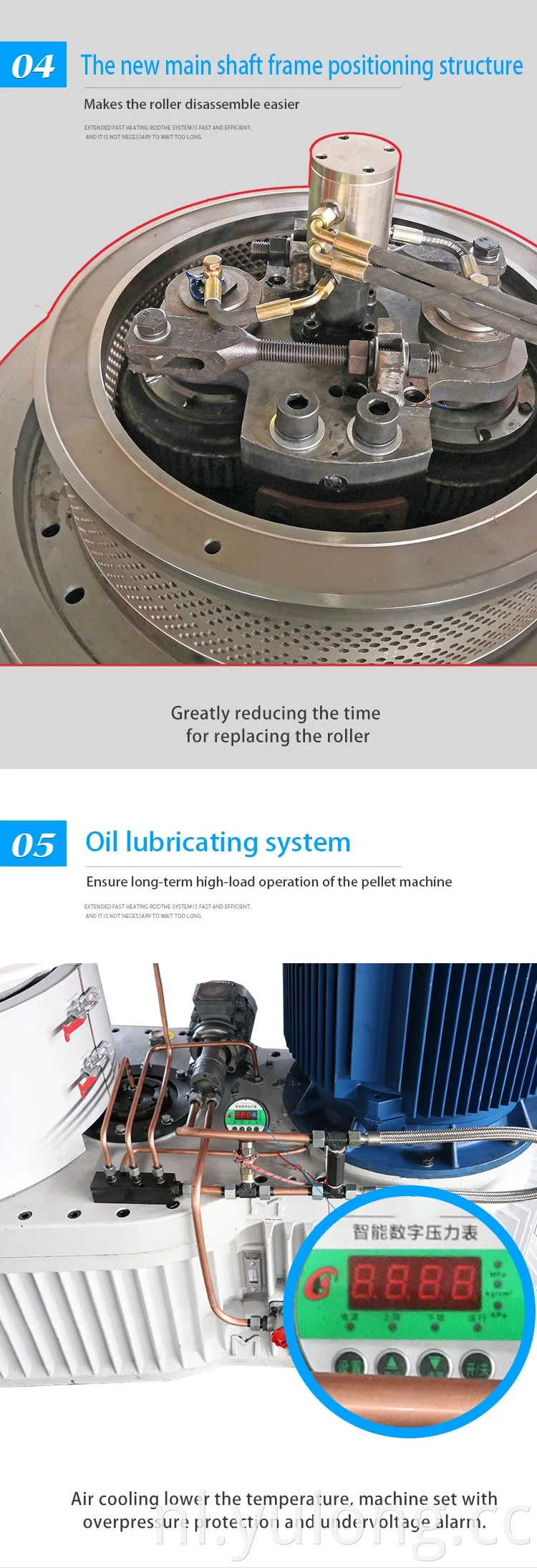

4 |

Ring die fixed, main shaft vertically, main shaft and roller rotating , the roller only can rotating inside of the ring die, so no deflection, no shaking, machine running more stably. |

|

5 |

Vertical ring die fixed, roller rotating, with centrifugal force, making the materials evenly distributed around inside the die, also the centrifugal force will help improve the capacity. |

|

6 |

Extremely compact kick-out device, more stable during working. |

|

7 |

The cover of kick-out device adopt 304 stainless steel, anti-wear and corrosion -resistant. |

|

8 |

The cover of kick-out device to be pressed one time forming, high strength. |

|

9 |

Two sets lubrication system--one is lubrication pump to lubricate rollers, the other is lubrication pipe to lubrication main shaft and gear box which ensure the pellet machine can work long time. |

|

10 |

Thin oil lubrication cooled by air, and equipped with overpressure protection and underpressure alarm, real-time display of circulating pressure, to ensure long-term high load operation of pellet mill. |

|

11 |

The position of pellet outlet and kick-out reducer can be adjusted according to customers` wishes or factory field situation. |

|

12 |

The main shaft adopt high stiffness load-bearing structure, diameter increased 15%. And the load-bearing surface of main shaft bearing added 1 time. More stable operation and lower failure rate, aimed to make the pellet machine output higher. |

|

13 |

The new positioning structure of main shaft supporting frame makes it easier to disassemble the roller and greatly reduces the time for users to replace the roller. |

|

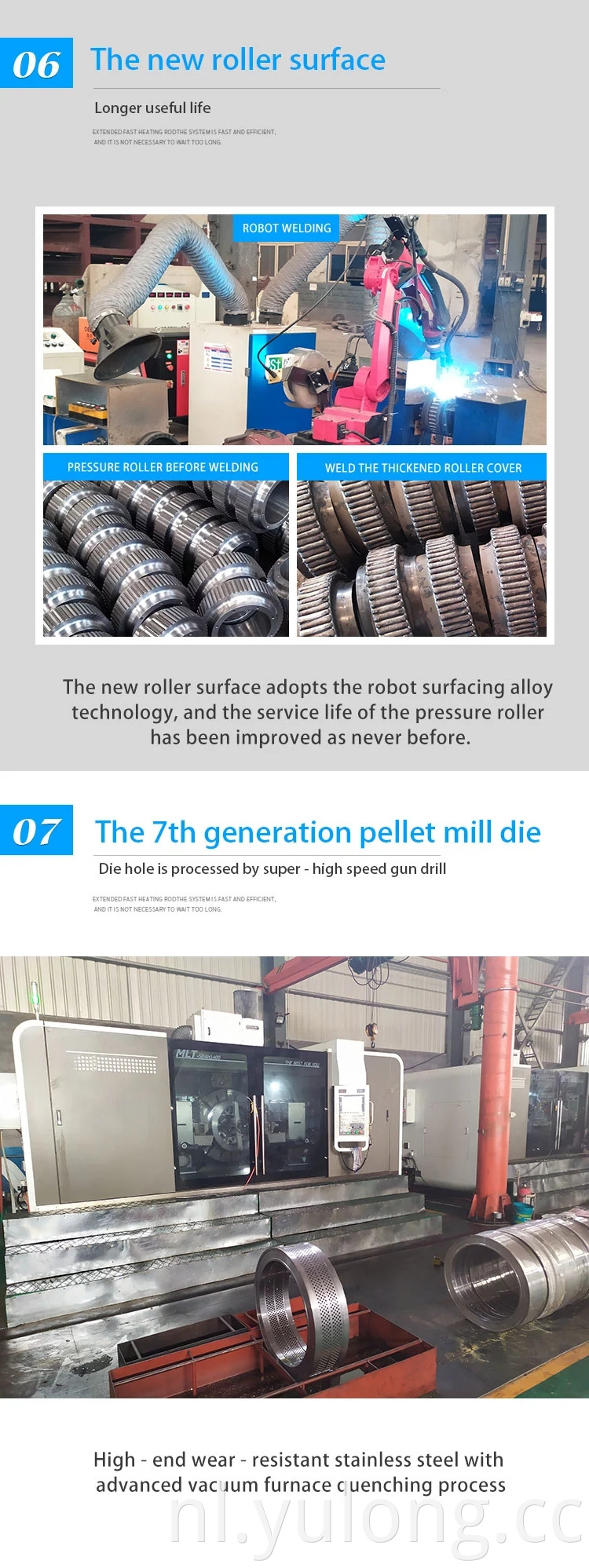

14 |

The new pressure roller surface adopts the technology of the robot surfacing alloy which extend the service lifetime of the roller. |

|

15 |

The mould all used high-end wear-resistant stainless steel plus advanced vacuum furnace quenching technology, hardness of surface and inside is the same. |

|

16 |

The mould hole is machined by ultra-high speed gun drill, and the it can be used after grinding slightly. |

Yulong verticale ring matrijs Biomassa Landbouw Gewas Afval pellet molen Specificaties:

|

Model |

Power(kw) |

Capacity(ton/h) |

Weight(ton) |

Dimension(mm) |

|

XGJ560(5th) |

90 |

1-1.5 |

5.3 |

2600*1300*2300 |

|

XGJ850(5th) |

220 |

2-3 |

14.5 |

3300*1400*3100 |

|

XGJ560(7th) |

132 |

1.5-2 |

4.5 |

2588*1250*1602 |

|

XGJ850(7th) |

250 |

3-4 |

13.5 |

2650*1850*2100 |

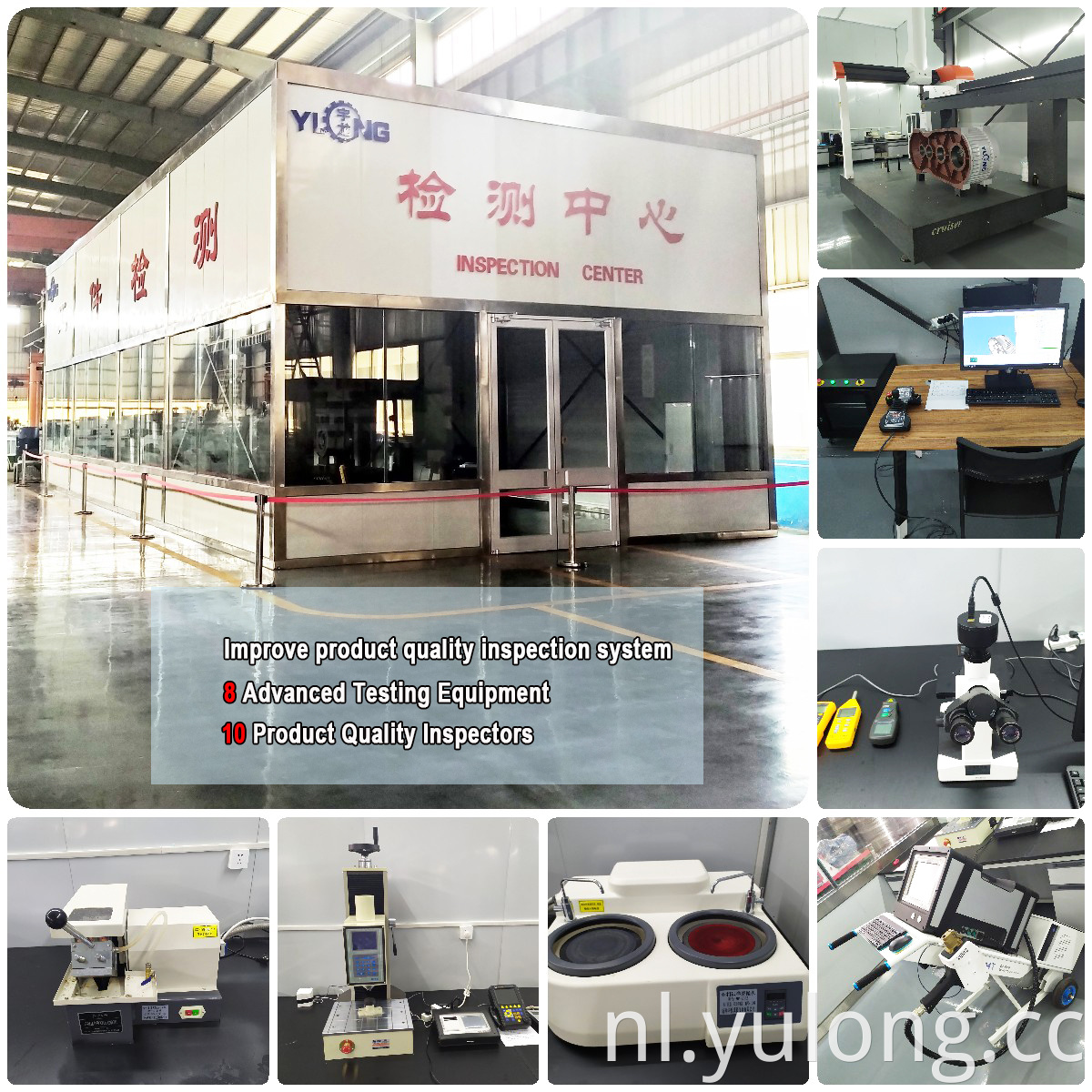

YULONG fabricage machines

YULONG inspectiecentrum

YULONG bedrijf

Yulong machine versterkt het transmissiesysteem

1. versnellingsstructuur: transmissie met parallelle as drie geharde tanden spiraalvormige vertraging, versnelling modulus toename, versnelling verbreding, versterking, transmissie sterkte is 3-5 keer de conventionele reducer.

2. Power input: het gebruik van efficiënte energiebesparende motor, plug direct aangesloten, coaxiale hoge, hoge snelheid as met parallelle as structuur, tandwielas zijn twee ondersteuning rotatie, hoge stijfheid, soepele en betrouwbare transmissie, verlaten de grotere power .

3.Power output: de deice output en de spil in één, om de beperkte vorm van verbinding te verlaten, nam de sterkte 2-3 keer toe.

4. Belangrijkste asversterking: de aslengte wordt verkort, de stijfheid wordt aanzienlijk verbeterd, hoge stijfheid van de as kan de slijtage van schimmel en rollen verminderen.

5. Flexibele installatie: de apparaatuitgang kan multi-hoekrotatie zijn, apparatuurinstallatie flexibeler en diverser.

Yulong machine produceren proces:

Product Categorie : Pelletmachine > Houtpelletsmachine

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.