Model NO.: MZLH420

Warranty: 1 Year

Customized: Customized

Condition: New

Color: Customized

Condition: New: Place of Origin:Jiangsu, China (Mainland)

Brand Name: Lywf: Model Number: Mzlh

Voltage: 380V: Power(Kw): 90-110kw

Certification: Ce: Warranty: 1year

Material: Bamboo, Wood, Rice Husk,etc: Type: Ring Die and Gear Drive

Wearing Parts: Ring Die and Press Roll: Pellet Size: 6, 8, 10, 12mm

Pellet Length: 30mm-45mm: Motor: Siemens or Wannan

Bearing: NSK: Container: 3-5PCS / Line

Trademark: WF

Transport Package: Wooden Case or Pallet for Your Choice

Specification: CE

Origin: Jiangsu, China

HS Code: 84361000

Model NO.: MZLH420

Warranty: 1 Year

Customized: Customized

Condition: New

Color: Customized

Condition: New: Place of Origin:Jiangsu, China (Mainland)

Brand Name: Lywf: Model Number: Mzlh

Voltage: 380V: Power(Kw): 90-110kw

Certification: Ce: Warranty: 1year

Material: Bamboo, Wood, Rice Husk,etc: Type: Ring Die and Gear Drive

Wearing Parts: Ring Die and Press Roll: Pellet Size: 6, 8, 10, 12mm

Pellet Length: 30mm-45mm: Motor: Siemens or Wannan

Bearing: NSK: Container: 3-5PCS / Line

Trademark: WF

Transport Package: Wooden Case or Pallet for Your Choice

Specification: CE

Origin: Jiangsu, China

HS Code: 84361000

MZLH420 Horizontal Ring Die Wood Pellet Machine Mill same with C.P.M.

Our company, Liyang Weifeng Equipment Co., Ltd, is specialized in all kinds of CE biomass fuel pellet production line, wood pellet production line, sawdust pellet production line, rice husk pellet production line, straw pellet production line, bark pellet production line, bamboo pellet production line. Sunflower husk pellet production line, peanut pellet production line, etc.

How to make wood pellets? The following process can tell you the exactly:

*Debarking process(if needed)

*Chipping process(if the log is larger than 150mm, wood chipper can chip it into 20-50mm)

*Grinding process(grind the material into small powder to feed in pellet mill)

*Drying process(if the moisture is higher than 17%, need drying)

*Pelleting process(6mm, 8mm, 10mm, 12mm pellets can be formed by our pellet mill)

*Cooling & Sieving process(the temperature after pelleting is high to 90° C, it needs cooling)

*Packing process

Technical parameter of MZLH420 Horizontal Ring Die Wood Sawdust Pellet Machine Mill same with C.P.M.:

| NO |

NAME

|

MZLH30

|

MZLH35 |

MZLH40 |

MZLH42

|

MZLH508

|

| 1 |

Capacity (wood pellet )

|

0.1-0.3

|

0.3-0.5

|

0.5-0.8

|

0.8-1.5

|

1.5-2.0

|

| 2 |

Power

|

37

|

55 |

75 |

90/110 |

110/132 |

| 3 |

Screw feeder Power

|

0.55 |

0.55

|

0.75 |

0.75 |

0.75 |

| 4 |

Pellet size

|

φ6, φ8, φ10, φ12

|

φ6, φ8, φ10, φ12

|

φ6, φ8, φ10, φ12

|

φ6, φ8, φ10, φ12

|

φ6, φ8, φ10, φ12

|

| 5 |

No. of press roll

|

2

|

2

|

2

|

2

|

2

|

| 6 |

Outer diameter of press roll

|

146

|

165

|

190

|

206

|

222

|

| 7 |

Mashing rae(%)

|

≤12%

|

≤12%

|

≤12%

|

≤12%

|

≤12%

|

| 8 |

Dimension(mm)

|

2006*800*1300

|

2165*895*1450

|

2302*970*2105

|

3150*1100*1650

|

3200*1300*1850

|

| 9 |

Weight(t)

|

2.1

|

2.5 |

2.8 |

3.1 |

3.5 |

| |

|

|

|

|

|

|

Introduction of MZLH420 Horizontal Ring Die Wood Sawdust Pellet Machine Mill same with C.P.M.:

1)This feed machine is equipped with screw feeder controlled by FC inverter with permanent magnet to removing iron impurities.

(2) Stainless steel conditioner makes even retention and sufficient cooking effect.

(3) Gear directly-connecting driving is adopted for high accuracy and efficiency. The output can increase 20% comparing to pellet mill driven by belts.

(4) High quality bearings(SKF/NSK), oil seal( from Germany) is adopted to makes operation smoothly.

(5) Main gear and pinion shaft adopt the carbonizing quenching with high accuracy, toensure smooth driving, low noise and long service life.

(6) S shape coupling is used with advantage of high capability of retrieve displacement.

(7) The die is quickly assembled and disassembled; die hoist is optional.

(8) Applicable for all kinds of high grade animal/livestock/aqua feed. Double or three layers of conditioner is optional.

(9) Speed-adjust feeding, adopted by this machine, can control the feeding capacity correctly to fit for different and meet the production requirement of pellets with different diameters.

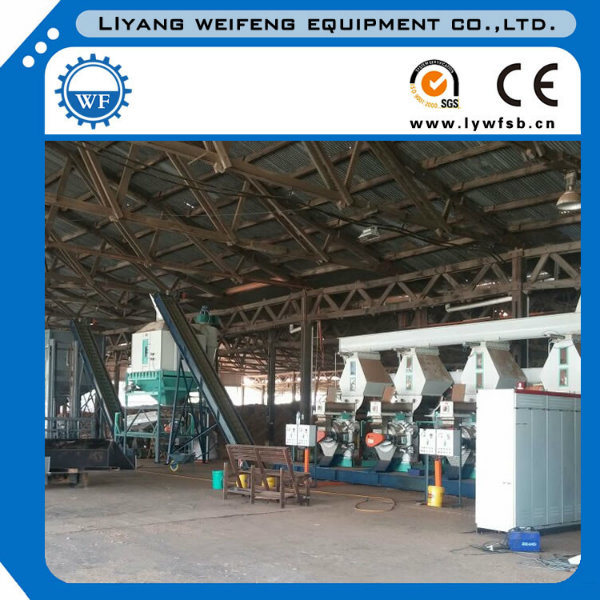

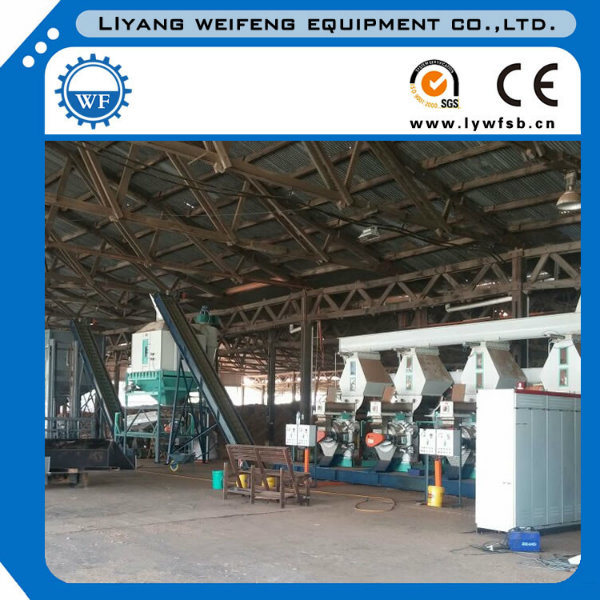

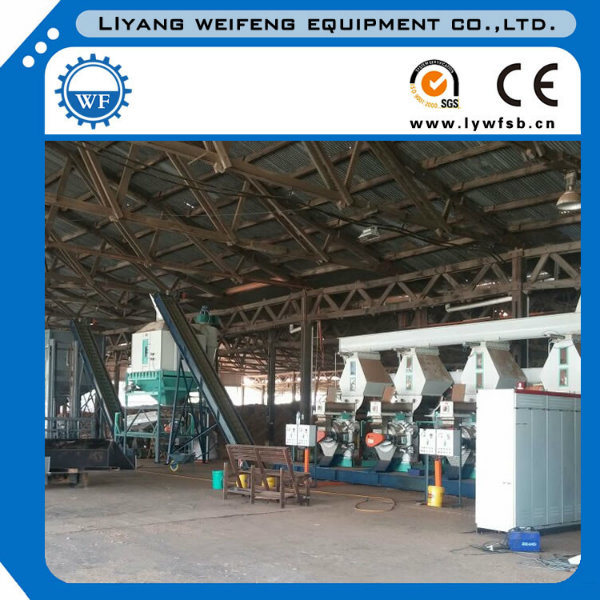

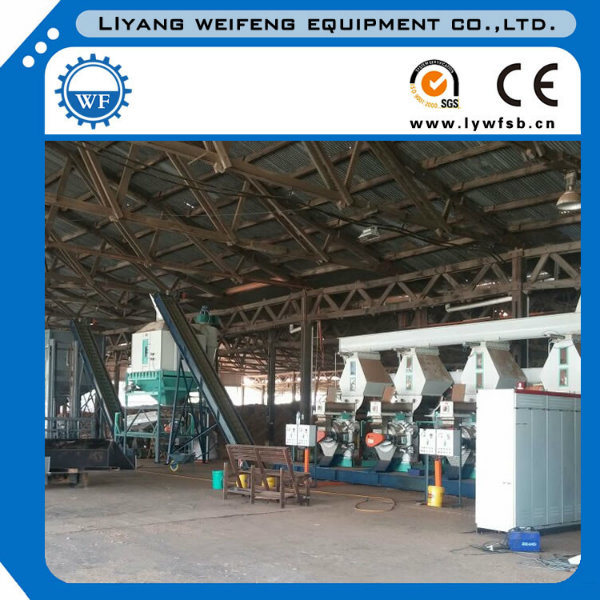

(10) CE approved On-site Wood Pellet project pictures:

If you're interested in our MZLH420 Horizontal Ring Die Wood Sawdust Pellet Machine Mill same with C.P.M., pls kindly tell us the following information:

1. What's the capacity you want?

2. What's the raw material?

3. What's the size of the raw material?

4. What's the moisture content?

5. What's the final pellet size do you want?

6. Automatic packing or manual packing needed?

7. What's your country voltage?

Liyang Weifeng Equipment Co., Ltd.

Welcome to visit our factory.

MZLH420 Horizontal Ring Die Wood Pellet Machine Mill same with C.P.M.

Our company, Liyang Weifeng Equipment Co., Ltd, is specialized in all kinds of CE biomass fuel pellet production line, wood pellet production line, sawdust pellet production line, rice husk pellet production line, straw pellet production line, bark pellet production line, bamboo pellet production line. Sunflower husk pellet production line, peanut pellet production line, etc.

How to make wood pellets? The following process can tell you the exactly:

*Debarking process(if needed)

*Chipping process(if the log is larger than 150mm, wood chipper can chip it into 20-50mm)

*Grinding process(grind the material into small powder to feed in pellet mill)

*Drying process(if the moisture is higher than 17%, need drying)

*Pelleting process(6mm, 8mm, 10mm, 12mm pellets can be formed by our pellet mill)

*Cooling & Sieving process(the temperature after pelleting is high to 90° C, it needs cooling)

*Packing process

Technical parameter of MZLH420 Horizontal Ring Die Wood Sawdust Pellet Machine Mill same with C.P.M.:

| NO |

NAME

|

MZLH30

|

MZLH35 |

MZLH40 |

MZLH42

|

MZLH508

|

| 1 |

Capacity (wood pellet )

|

0.1-0.3

|

0.3-0.5

|

0.5-0.8

|

0.8-1.5

|

1.5-2.0

|

| 2 |

Power

|

37

|

55 |

75 |

90/110 |

110/132 |

| 3 |

Screw feeder Power

|

0.55 |

0.55

|

0.75 |

0.75 |

0.75 |

| 4 |

Pellet size

|

φ6, φ8, φ10, φ12

|

φ6, φ8, φ10, φ12

|

φ6, φ8, φ10, φ12

|

φ6, φ8, φ10, φ12

|

φ6, φ8, φ10, φ12

|

| 5 |

No. of press roll

|

2

|

2

|

2

|

2

|

2

|

| 6 |

Outer diameter of press roll

|

146

|

165

|

190

|

206

|

222

|

| 7 |

Mashing rae(%)

|

≤12%

|

≤12%

|

≤12%

|

≤12%

|

≤12%

|

| 8 |

Dimension(mm)

|

2006*800*1300

|

2165*895*1450

|

2302*970*2105

|

3150*1100*1650

|

3200*1300*1850

|

| 9 |

Weight(t)

|

2.1

|

2.5 |

2.8 |

3.1 |

3.5 |

| |

|

|

|

|

|

|

Introduction of MZLH420 Horizontal Ring Die Wood Sawdust Pellet Machine Mill same with C.P.M.:

1)This feed machine is equipped with screw feeder controlled by FC inverter with permanent magnet to removing iron impurities.

(2) Stainless steel conditioner makes even retention and sufficient cooking effect.

(3) Gear directly-connecting driving is adopted for high accuracy and efficiency. The output can increase 20% comparing to pellet mill driven by belts.

(4) High quality bearings(SKF/NSK), oil seal( from Germany) is adopted to makes operation smoothly.

(5) Main gear and pinion shaft adopt the carbonizing quenching with high accuracy, toensure smooth driving, low noise and long service life.

(6) S shape coupling is used with advantage of high capability of retrieve displacement.

(7) The die is quickly assembled and disassembled; die hoist is optional.

(8) Applicable for all kinds of high grade animal/livestock/aqua feed. Double or three layers of conditioner is optional.

(9) Speed-adjust feeding, adopted by this machine, can control the feeding capacity correctly to fit for different and meet the production requirement of pellets with different diameters.

(10) CE approved On-site Wood Pellet project pictures:

If you're interested in our MZLH420 Horizontal Ring Die Wood Sawdust Pellet Machine Mill same with C.P.M., pls kindly tell us the following information:

1. What's the capacity you want?

2. What's the raw material?

3. What's the size of the raw material?

4. What's the moisture content?

5. What's the final pellet size do you want?

6. Automatic packing or manual packing needed?

7. What's your country voltage?

Liyang Weifeng Equipment Co., Ltd.

Welcome to visit our factory.